ATP System Components

We thought outside of the box, and then we shrunk it. At Hygiena®, we approached the issues surrounding an ATP system in a different way. By looking at all 3 components that make up an ATP system and introducing new state-of-the-art technology with patented designs and chemistry, we’ve created an ATP system that is smaller, more durable, and more sensitive than all other systems on the market.

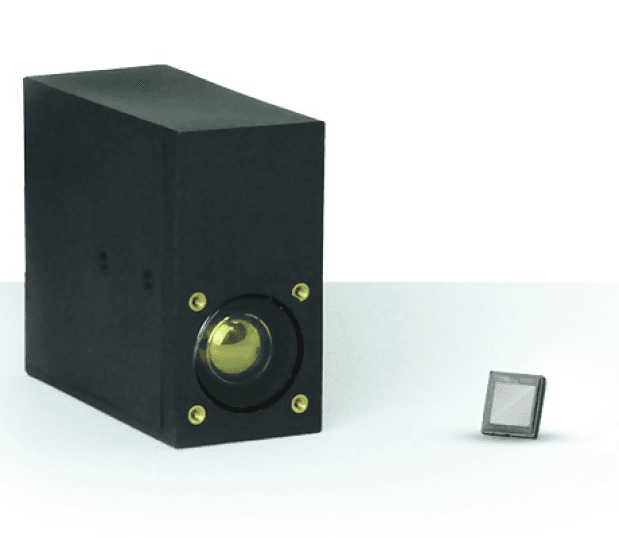

Instrument Sensor

The instrument (luminometer) quantifies the bioluminescent reaction from the ATP test. A luminometer should see low levels of light, be user-friendly, and durable to work in all types of environments. Historically and even today, luminometers have used Photomultiplier Tube (PMT) sensors to detect low levels of light. However, with advancements in technology, new solid-state Photodiodes (PD) now have the ability to detect similar low levels of light and offer lots of additional benefits over PMT. Hygiena® instruments use advanced PD sensors and electronics, giving them the ability to detect lower levels of light than PMT-based instruments. The chart below lists the pros and cons for each sensor.

| Photomultiplier Tube (PMT) | Photodiode (PD) | ||

| PROS | CONS | PROS | CONS |

| Sensitive to low levels of light | Fragile | Robust | Detects limited frequencies – suitable for bioluminescence only |

| Detects multiple frequencies – suitable for bioluminescence and chemiluminescence | Large, heavy | Small, light | Slightly less sensitive than PMT sensors |

| Requires high voltage | Requires low voltage (<5 volts) | ||

| Drifts out of calibration | Stays in calibration | ||

| Requires yearly or bi-annual maintenance | Does not require yearly maintenance (cost savings) | ||

| Impacted by magnetic fields (e.g., manufacturing equipment) | Low cost | ||

| Expensive | Solid state | ||

| Unstable |

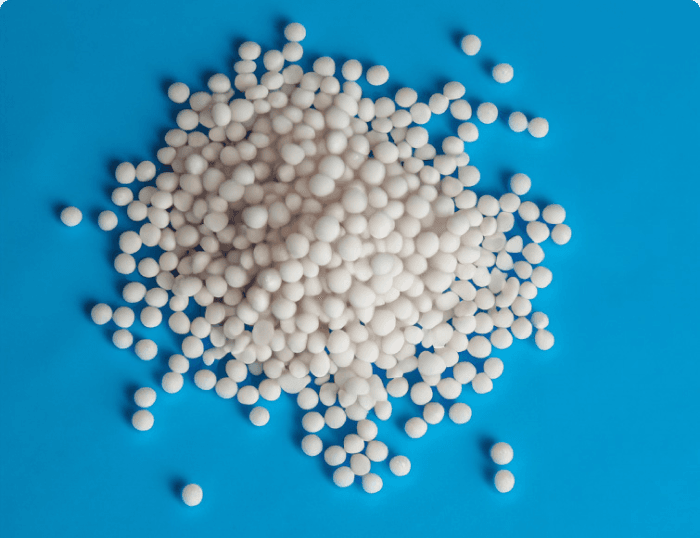

Bioluminescence Chemistry

Chemistry in test devices is also a critical element of system performance, as it facilitates the bioluminescent reaction that is measured by the instrument. The more reliable the chemistry, the more reliable the results. Two types of chemistry on the market are lyophilized chemistry and liquid-stable chemistry.

Lyophilized

Lyophilization has historically been the technology used to stabilize enzymes prior to use. Water is quickly evaporated out of the sample, leaving a pellet that can be reconstituted with a liquid. The pellet requires complex, expensive manufacturing, dry storage, and rehydration at the point of use that causes larger variability from test to test.

Liquid-stable

Liquid-stable chemistry eliminates the need for lyophilization and stabilizes the enzymes in a liquid format. This eliminates costly manufacturing steps and reconstitution of the enzyme giving more reproducible results and better accuracy. Fewer manufacturing steps also reduces test costs.

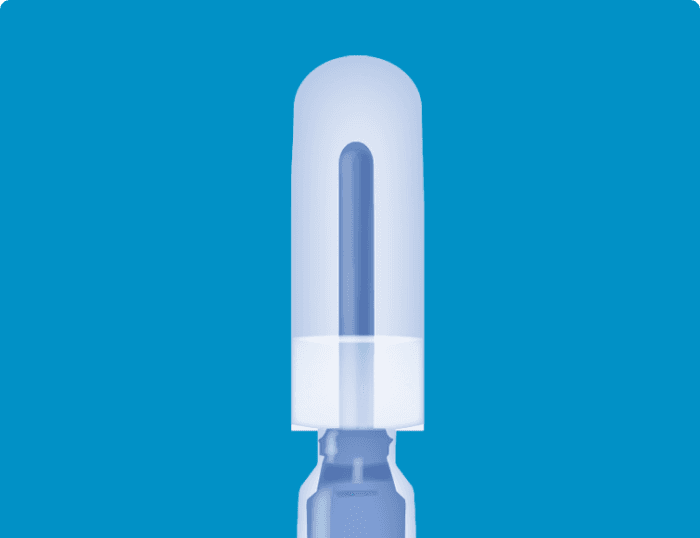

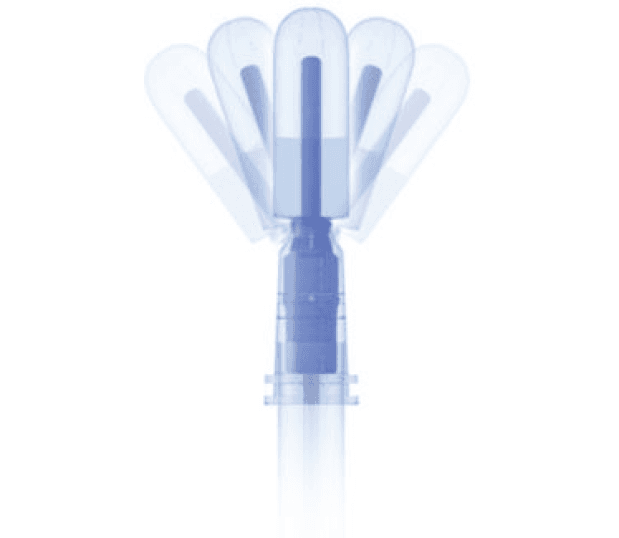

Test Device

The final element of system performance is the test device. Superior device design will have excellent sample collection and recovery, low background signal, and ease of use. The Hygiena® test design maximizes sample collection and recovery while using patented Snap-Valve™ technology to make activation easy. Our devices eliminate extraneous materials, improve efficiency, minimize variability, and lower costs.

Bottom Line

Superior ATP cleaning verification performance is the result of three key components: instrument sensor, bioluminescent chemistry and design of test device. The Hygiena® cleaning verification system maximizes all three components to deliver unbeatable performance. But, don’t take our work for it, review the data.