Key Benefits

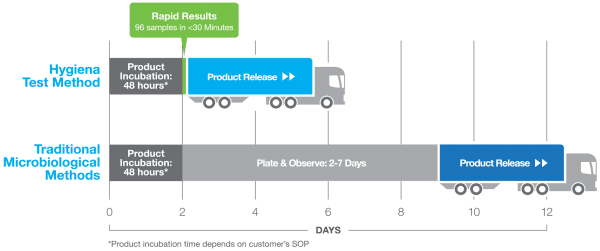

Reduce Inventory and Warehouse Costs by Releasing Products Days Faster

The Hygiena™ Innovate rapid microbial screening systems are designed to meet the needs of today’s manufacturers for fast, efficient, and safe product release. From screening raw materials and work-in-process inventory to releasing finished goods, the Innovate System is a great fit for packaged dairy, food, and beverage products where there is a low expectation of bio-burden such as in ultra-high temperature (UHT) or extended shelf-life (ESL) pasteurized products.

Innovate Cost Savings

For more than two decades, companies who package food, beverage, and dairy products have preferred the reliable results generated by their high-throughput systems to confirm they are shipping safe products to market. In the first five years of implementation, the average Innovate customer in the dairy industry saves more than $500,000.

Innovate Can Test It

Cheese sauce. Pulpy juices. Thick puddings. The Innovate System can test them all. No other rapid method covers the range of products and applications we can test. The Innovate System is flexible and easy to use, even with hard-to-test product types that are:

- Clear, opaque or highly pigmented

- Filterable or non-filterable

- Soluble or non-soluble

- High or low pH

- Preserved or non-preserved

- Products in aseptic packaging

Implemented Worldwide

Rapid microbial screening is easy to adopt and a smart strategy for dairy, beverage, and food companies. Our network of representatives and distribution partners around the world are ready to support you and make your implementation and validation process run smoothly. Support options include:

- Instrument and software installation qualification and operation qualification (IQ/OQ)

- A step-by-step evaluation guide

- Three days of on-site, in-person instruction for you and your lab staff, including the initiation of validation

Compatible Products for Innovate™

All Products

Accessories for Innovate™

| Product No. | Product | Quantity |

|---|---|---|

| KIT4014 | ATP Positive Control Kit | 1 |

| KIT4012 | Monthly Maintenance & Cleaning Kit | 1 |

| KIT4043 | Microwash 400 mL | 1 |

| KIT4018 | Microwash 400 mL (6-pk) | 1 |

Product Library

| Title | Categories | Language | Region (SDS) |

|---|---|---|---|

| Safety Data Sheet | English | USA | |

| Technical Bulletin | English | ||

| Technical Bulletin | English | ||

| Technical Bulletin | English | ||

| Technical Bulletin | English | ||

| Technical Bulletin | English | ||

| White Paper | English | ||

| White Paper | English | ||

| White Paper | English | ||

| White Paper | English |