Rapid Indicator

Rapid Results, Robust Reliability - Reliable Food Safety with Every Swipe.

Beyond the Surface: Rapid Indicator Testing for Proactive Food Safety Management

Rapid Indicator Testing is a pivotal process in environmental monitoring, crucial for ensuring that food products are free from spoilage and pathogenic microorganisms. This testing is indispensable for maintaining the highest standards of food safety and quality, particularly in food production where the risk of contamination is a significant concern. By identifying potential hazards quickly, Rapid Indicator Testing facilitates timely corrective actions, safeguarding consumer health and upholding brand integrity.

What is Rapid Indicator Testing?

Rapid Indicator Testing refers to the swift detection and enumeration of specific microorganisms or groups of microorganisms, known as "indicator organisms," that can signal the presence of contamination or suggest the potential for spoilage and foodborne illnesses.

Indicator organisms or early warning indicators are selected based on their correlation with pathogenic bacteria or poor sanitary conditions. These can include but are not limited to coliforms, Enterobacteriaceae, and other organisms that, when detected, prompt immediate investigation and intervention. The speed and accuracy of Rapid Indicator Testing are essential for maintaining a robust Hazard Analysis and Critical Control Points (HACCP) system and meeting regulatory requirements.

This testing method is fast-acting, giving quality managers in food production the ability to receive actionable data in a significantly shorter time frame compared to traditional culturing methods. With products like Hygiena's MicroSnap® and InSite®, Rapid Indicator Testing becomes an integrated part of the workflow, enabling the monitoring of critical control points and ensuring the food safety and quality that consumers trust.

How Does Rapid Indicator Testing Work?

Rapid Indicator Testing harnesses the latest advancements in microbiology and biotechnology to quickly assess the potential for contamination. Here’s a step-by-step overview of how this transformative process works in practice, particularly utilizing Hygiena’s MicroSnap product line:

From Swab to Results – The ATP Verification Process

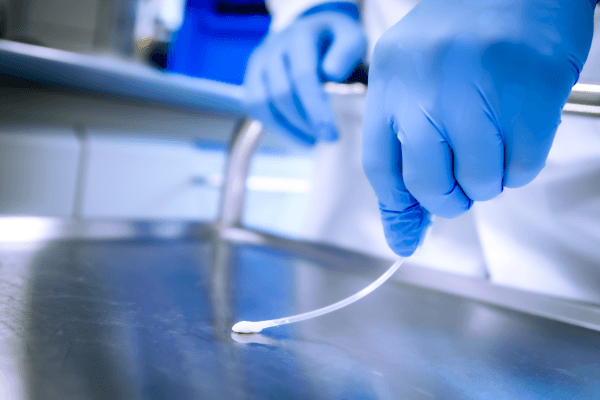

- Sample Collection: Utilizing specialized swabs or testing devices, technicians collect samples from surfaces, equipment, or directly from the food products.

- Enrichment: The collected sample is then introduced to a unique culture medium through Hygiena’s patented Snap-Valve technology. This technology releases enrichment broth at the snap of the swab bulb, immersing the sample in nutrients that promote bacterial growth if present.

- Incubation: After enrichment, the swab is incubated for a short period. The precise time depends on the specific bacteria being tested but is remarkably quick, often just a few hours for results.

- Activation/Detection: Post incubation, MicroSnap detects bacteria through a luminogenic reaction. If bacteria are present, they will emit light, measured in Relative Light Units (RLUs). The intensity of this light correlates with the number of bacteria in the sample.

- Quantification and Analysis: The emitted light is quantified using a compatible luminometer like the EnSURE® Touch. This step gives a precise count of indicator organisms, bypassing the subjective interpretation often associated with traditional plating methods.

Through this method, MicroSnap not only delivers reliable and reproducible results but also ensures they are obtained faster than traditional methods, without sacrificing accuracy. It's a comprehensive, start-to-finish system that provides peace of mind and empowers proactive food safety measures.

Benefits of Rapid Indicator Testing

- Accelerated Readiness: Results from Rapid Indicator Testing are achieved much faster than traditional methods, often within the same working day. This expedience is essential in dynamic food production settings where timely responses to potential hazards are critical.

- Simplicity in Procedure: The tests are user-friendly, requiring minimal training. This accessibility allows them to be integrated into regular workflow routines without the need for specialized staff.

- Precision and Reliability: These tests are finely tuned to detect even small quantities of indicator organisms, providing the confidence that comes from precise and trustworthy results.

- Cost Savings: In-house testing capabilities can significantly reduce the need for outsourced laboratory services, leading to cost reductions related to testing and potential downtime associated with waiting for external lab results.

- Regulatory Adherence: The tests help ensure compliance with strict food safety regulations, thereby mitigating the risk of non-compliance penalties and contributing to a company’s reputation for quality and safety.

- Data Integration and Trend Analysis: Modern Rapid Indicator Tests can be integrated with data analysis software, such as SureTrend®, providing actionable insights that help in making informed decisions and in the continuous improvement of safety protocols.

- Preventive Action Empowerment: Early detection empowers facilities to take preemptive measures before small issues become significant problems, thereby maintaining product integrity and consumer trust.

Indicator Testing for your Workflow

In a comprehensive testing workflow, MicroSnap fits in seamlessly, delivering prompt and precise microbial counts, At the same time, EnSURE Touch acts as the versatile command center for various test devices, and SureTrend® software provides the ultimate platform for data analysis and trend tracking, making the entire process from sample to decision efficient and integrated. Together, they form a robust trio that enhances the responsiveness and accuracy of environmental monitoring programs.

Sample Collection

Sample collection devices for convenient and reproducible use that come with all reagents necessary for the incubation and detection of indicator organisms.

Detection Instrument/ Luminometer

EnSURE® Touch is an advanced monitoring system that collects, analyzes and reports data from ATP verification test devices like UltraSnap or MicroSnap.

Analytics

SureTrend® is a platform that provides a gateway to actionable insights. This software provides secure data integration from multiple sources and facilities.

Key Takeaways for Rapid Indicator Testing

Embracing indicator organism testing positions Quality Managers to proactively manage food safety risks, uphold high standards of quality, and sustain their brand's reputation in a competitive market.

- Rapid Response: Rapid Indicator Testing, with tools like MicroSnap, enables swift detection of potential contamination, allowing for immediate corrective actions and minimizing production disruptions.

- Data-Driven Decisions: The ease of data collection and analysis facilitates informed decision-making, enhancing the effectiveness of food safety programs and supporting continuous improvement.

- Regulatory Compliance: These technologies not only streamline the testing process but also assist in maintaining compliance with food safety standards, safeguarding against costly penalties and recalls.

Case Studies and Applications for Rapid Indicator Testing

Discover how ATP verification is revolutionizing environmental monitoring across industries through Hygiena's compelling case studies and diverse applications.