Food Safety

Validation vs Verification in a Food Factory Webinar

Join Hygiena and Comaine Van Zijl, Allergen Management Specialist at FACTS SA, discussing the importance of validation and verification in a factory.

We had an interesting discussion following the presentation and you can find additional Q&A below:

You say easy to clean areas should not be tested. With manual cleaning, there is the human element, where complacency can be an issue - what's your thought on preventing an error there?

It is not wrong to test easy-to-clean surfaces, however, it is important not to only test easy-to-clean areas. Gaining insight into how clean the difficult to clean areas provide more information on the overall efficiency of the cleaning regime. I agree that complacency should be considered and monitored. This can be greatly overcome by appropriate training, oversite and post-cleaning visual inspections or physical audits. Testing plays an important role to confirm the absence of allergenic food residues. It is important to note that there is a substantially higher risk associated with gross residue cross-contact compared with minor residue cross-contact.

As heat exaggerates are more difficult to remove allergens, do you have tips to make it easier?

Specific tips will depend on the specifics of the processing step, allergen, product formulation, etc. The general principles are as follows. Proteins can become tightly bound to surfaces through several attractive forces. These play an instrumental role in the accumulation of residues on equipment surfaces. Forces may arise between the material and the surface (forces of adhesion) and between the components of the material themselves (forces of cohesion) and can give rise to the formation of multilayer attachments. Counter forces (energy) are required to break the bonds between the components of food residues and the food contact surface. Thus, for effective cleaning, enough energy must be employed. Three types of energies that can be used for cleaning are:

- Mechanical energy: Shear force caused by swabbing, scrubbing, fluid flow or pressure (e.g. water jet)

- Thermal energy: e.g. elevated temperature

- Chemical energy: Chemical action of detergents

An adequate combination of the above energies will facilitate effective cleaning. The balance of energies depends on the physical process and detergent type; some involve low chemical energy (such as neutral detergents) combined with high physical energy (scrubbing) and others high chemical energy (acidic descaler) with little physical energy. The greater the attachment of residues to the surfaces, the greater the combined energy required for cleaning. Removal of proteins is best accomplished using alkali-based detergents. Chlorinated alkali detergents are considered excellent choices for the removal of proteins from food surfaces, particularly when these have been heated. Alkaline detergents with peptising and wetting agents increase wettability and suspendability of protein soils, and caustic detergents with peroxide boosters or chlorine are recommended to hydrolyse proteins, thereby enhancing cleaning.

Can swab samples be reliably quantified by ELISA method?

Unfortunately not. ELISA protocols require very specific starting material (sample) amounts to be used to yield quantitative results. When testing a swab it is unknown how much material is present on the swab, thus accurate quantification is not viable.

Is there any recommended method to eliminate the allergens from cleaning tools before use that we should consider?

It is recommended that cleaning tools are appropriately cleaned at suitable intervals. Cleaning of tools must also be, recorded, monitored, validated and verified. Cleaning tools are normally cleaned by manual means. For manual cleaning to be effective, the type of detergent should be carefully considered, and there should be sufficient contact time. Visually inspection of tools is necessary to ensure that they are visually clean and void of particular cross-contact. Some facilities use cleaning tools that are distinguishable (e.g. colour coding) from those used for cleaning non-allergens. Colour coding can be an effective way of designating such equipment but should be functional.

What can cause false positive/false negative results for allergen swabs?

It depends on the method used. Matrices interference, protein structure, antibody cross-reactivity, etc., can potentially lead to false results.

The content of protein is a key factor. What do we need to consider is the protein content in the food or the content protein on the allergen itself?

When reviewing allergen cross-contact risk you will consider the amount of protein contributed by the allergenic materials. I.e. peanuts contain ± 25% protein.

Do you have any methodology to trace allergens residue presence on the surface or equipment when preparing the allergen request?

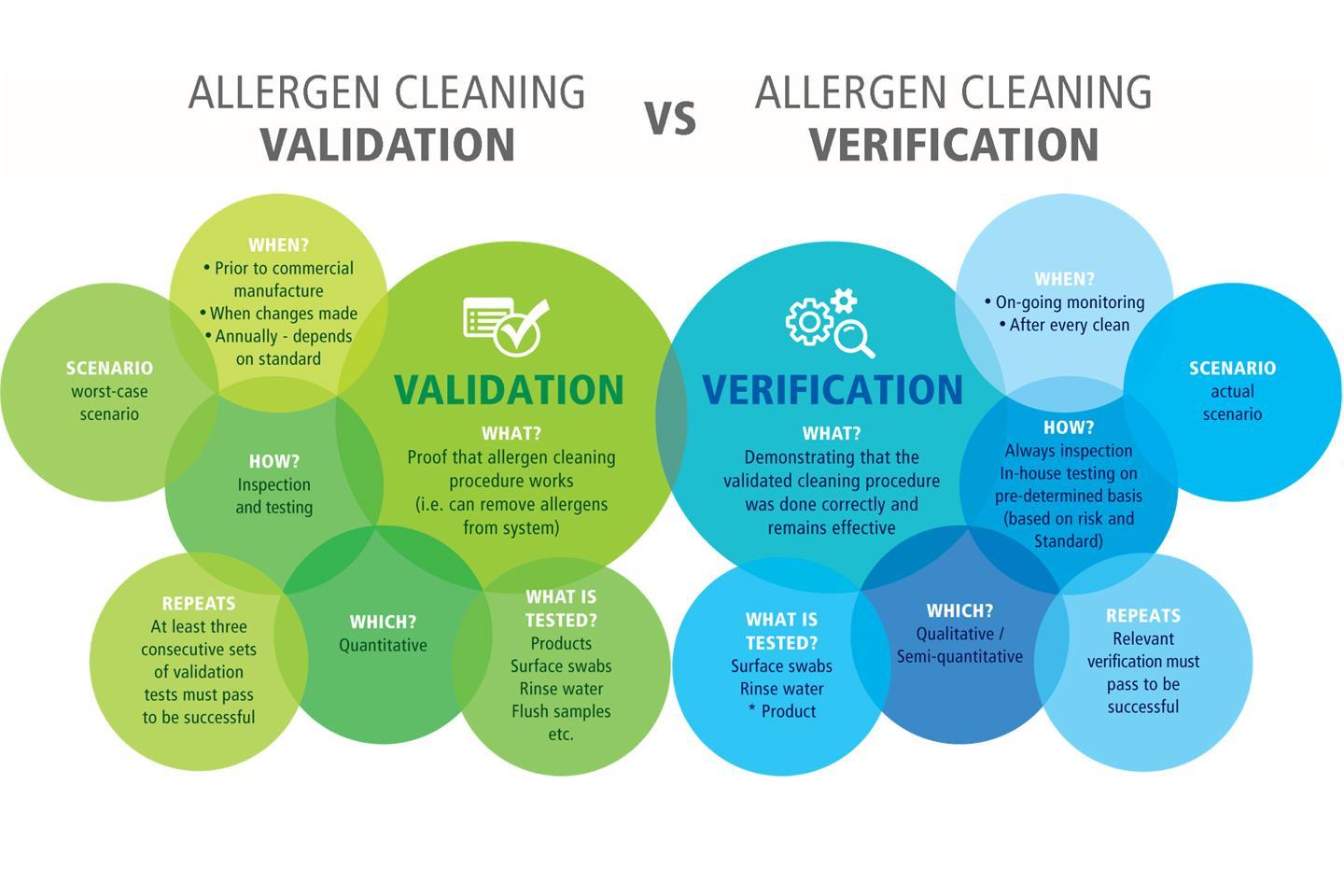

There are 2 types of systems we recommend for allergen cleaning verification/monitoring.

Allergen-Specific Lateral-Flow Devices (LFD): LFD is qualitative or semi-quantitative immunochromatographic tests, based on ELISA. They are easy to use, in comparison with their full ELISA counterparts; and they generate results in very little time, without expensive equipment. A set of coloured lines is produced, indicating whether the target allergen was present in the sample or not. The intensity of the line in the test zone is directly proportional to the concentration of the allergen. Semi-quantitative results can be produced by exposing the device to varying amounts of the sample extract, or by using a colour-intensity reader.

Total Protein Swabs: This system detects protein on surfaces and in the rinse water. The rationale is that since most allergens are proteins, a sample found to be protein-free could also be expected to be allergen-free. The system is easy to use, sensitive, and often the most cost-effective option, but it's not suitable for all environments - for example, the meat and poultry industry.

Checking that surfaces are visually clean will be the first step. In addition to that, I believe a total protein swab system will add a lot of value to verify the presence of allergens on surfaces. I recommend reaching out to Hygiena to inquire about the AllerSnap and PROClean systems.