Food Safety

3 Reasons Why Rapid Microbiological Testing is Essential for UHT vs ESL 'Milk' Products

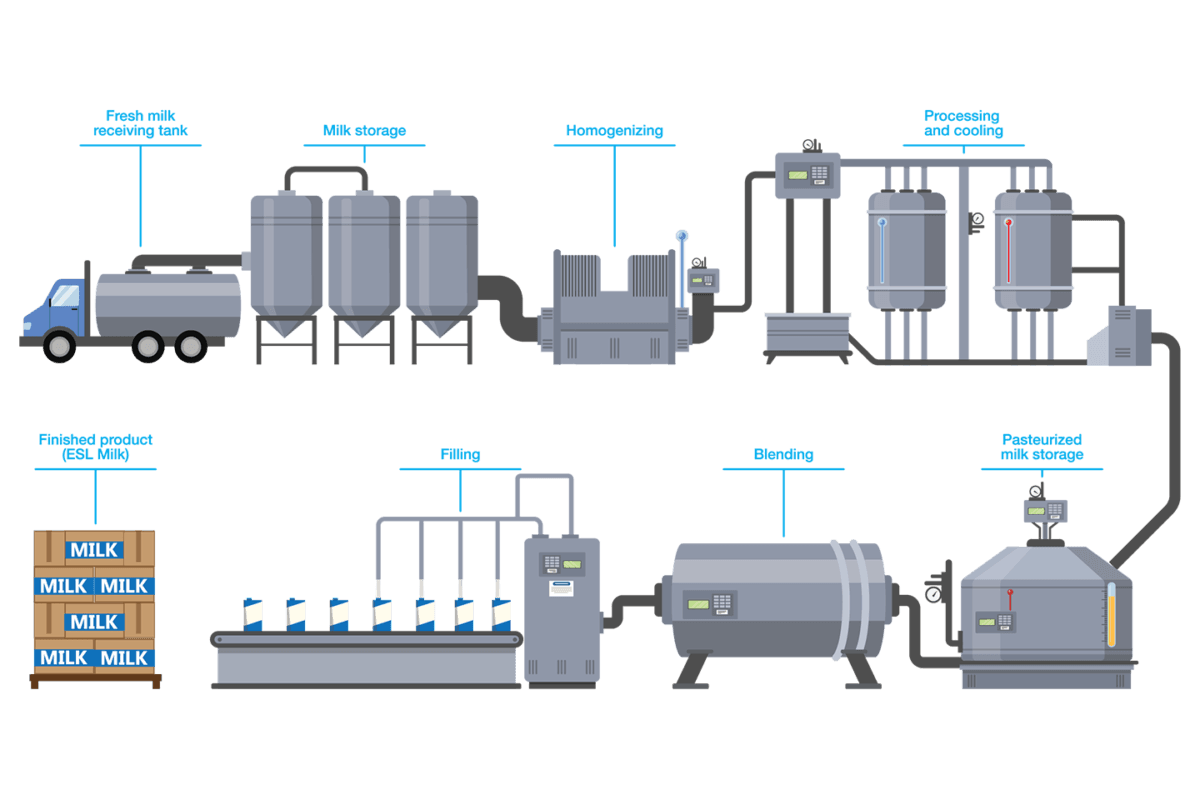

The global aseptic food and beverage packaging market is expected to reach $35 billion by 2025 partially due to the increased popularity of dairy products. This has fueled the demand for products with longer shelf lives and room temperature storage. While ideal for many foods and beverages, aseptic processing poses both advantages and disadvantages for milk and milk-derived beverages. Milk products are generally required to be processed by thermal methods such as pasteurization, as has been done for decades, which limits shelf life, chilled distribution, and refrigerated storage after purchase. Plus, the shelf life and quality of pasteurized milk can be affected by spore load in the raw milk, pasteurization conditions, contamination, and particularly distribution temperature. To overcome these challenges, new processing methods are being evaluated to further reduce or eliminate microbes that can cause food spoilage and disease. Two thermal processing methods are UHT (Ultra High Temperature) and UP (Ultra-Pasteurization). While UHT milk has been around for a while, it is now making a resurgence along with Extended Shelf Life (ESL/UP) milk, the latter playing an important role in the dynamics of dairy markets as they develop new processing and packaging methods. However, even with improvements in processing methods, there can be advantages and disadvantages to manufacturing UHT and ESL milk products.

Advantages of UHT milk include:

- Less processing time

- Extended shelf life

- Reduced microbial load

- Safer than other milk

- No need for refrigeration for storage

- Cheaper/wider variety of packaging options

Disadvantages of UHT milk include:

- Altered milk flavor/quality

- Decreased nutritional value

- Expensive process- complex, technical equipment, high energy use

- Anonymous milk origin due to batching

Advantages of ESL milk include:

- Organoleptic properties similar to pasteurized milk

- Extended shelf life

- Less expensive than UHT processing

Disadvantages of ESL milk include:

- Potential for contamination

- Potential for flavor issues

- Texture and appearance defects after prolonged storage

- Difficulty in remaining competitive (operational complexities)

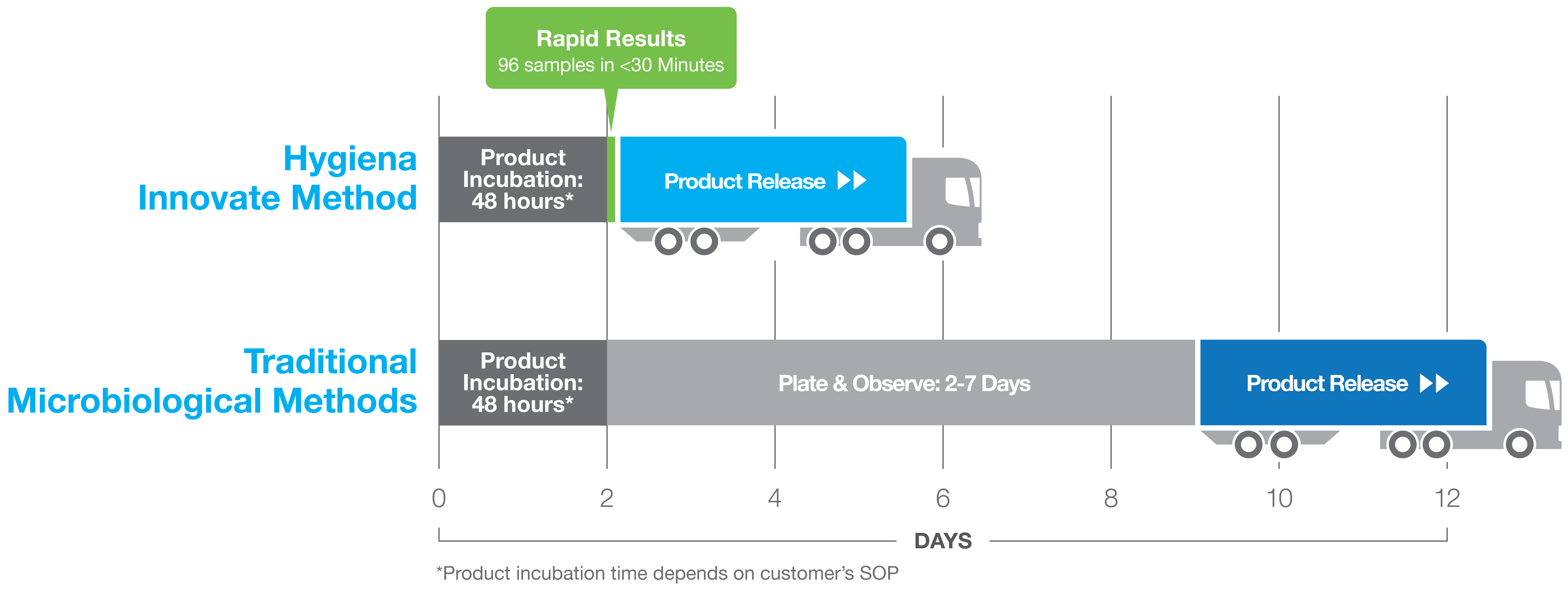

Second, while aseptic processing is a safe, high-quality, cost-effective method for food processing, there are still risks of contamination during manufacturing and production. To address this risk, food manufacturers must test each product for sterility before releasing it for sale. Traditional methods can take up to 15 days for results and are prone to error due to the manual handling of samples. These standard plating methods require different enrichment media plus long plate incubation times (7-14 days), and long detection/confirmation times (2-5 days) to target aerobic or anaerobic bacteria and yeast or mold. Other testing methods, pH and visual inspection have similar risks of errors as not all microorganisms cause a pH shift and visual inspection can miss low levels of contamination. To reduce time to results and streamline laboratory testing, a rapid method is necessary. The Innovate System from Hygiena™ offers both. Results can be obtained in less than 30 minutes with the ability to run 96 samples at once with no secondary incubation needed. In addition, the testing can be performed on a diverse product matrix - from UHT milks and creams to sauces, soups and broths, juices and beverages.

Rapid testing allows manufacturers to rapidly confirm the quality of the final product and release it quickly to market. Cost savings go beyond the rapid release of products - it means less safety stock, lower warehouse costs, and increased confidence in product safety. Third, to address microbiological risks in final products, it is ideal to have rapid testing that can be used for testing multiple matrices, specifically, those being manufactured in any of your food processing facilities. These methods should be verified and validated to ensure testing is consistent, accurate and a true reflection of microbial load in any product package before it is distributed for consumer use. Tied to the validation is the need for the most rapid testing that fits your requirements. When it comes to the Innovate System, Hygiena™ worked with several dairy and dairy-alternative partners to test time to results for various beverages (UHT milk, ESL milk, oat milk and soy milk) to determine if results obtained with the Innovate System are superior to traditional culture methods or pH testing with respect to the level of detection and shortest time to results.

In all cases, for all microorganisms tested (except for Clostridium sporogenes in ESL oat milk), the Innovate System was able to detect low spike levels (~10 CFU per pack) at a 24 hour time mark. RLU values in the spiked products exceeded the uncontaminated product RLU thresholds, set as three times the baseline values. Read the details of each study here:

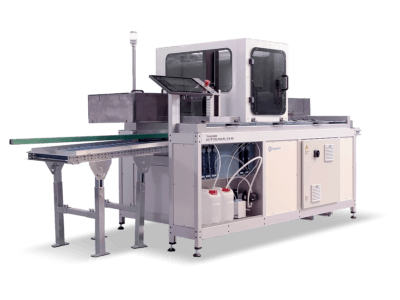

As a result of rapid detection of low levels of contamination at 24 hours, the cost savings for any facility is significant. While QC costs are similar, the investment in finished goods and safety stock are significantly reduced along with the warehouse space costs. In addition, positive release of product helps prevent recall cost and protect the brand that adds significant benefit to the introduction of a rapid testing system such as the Innovate System. As an additional advantage, high-volume facilities can automate product sampling using the Innovate Autosampler III. Learn more about the Innovate System and the Autosampler III here.

In summary, the 3 major reasons for rapid microbiological testing of dairy or dairy-alternative products are:

- Full microbiological testing results must be obtained before releasing product for sale. More rapid results mean less holding time, less warehouse space needed and quicker release for sale.

- Reducing time to results with the ability to test 96 samples in 30 minutes means you can screen for multiple microorganisms that may be present as contaminants in final product at the same time and quickly. In addition, for large sample volumes, sample processing can be automated with the Innovate Autosampler III.

- Validated methods for dairy and dairy-alternative products can have results in 24 hours rather than in days as with traditional methods. In addition, numeric values can help indicate the level of contamination for further tracking and trending. Overall, cost reduction and reduced time to results are essential for dairy and dairy-alternative food processors - simplifying operational needs.

Looking to learn more? Read our article on the savings you can see - Faster Results, Lower Costs, Improved Risk Mitigation, then check out our whitepaper about UHT vs ESL beverages: Advantages, Disadvantages and a Unified Testing Platform.