Rapid, Validated Control for Ready-to-Eat Food Safety

Ensure every ready-to-eat product is safe, compliant, and ready for release with fast, reliable testing across hygiene, pathogens, and allergens.

The Cost of Delays in Ready-To-Eat Production

Facilities handling ready-to-eat foods have no margin for error. Multi-ingredient recipes, frequent changeovers, and complex supply chains create the perfect storm for contamination, often without a final kill step. Even one missed hotspot or a slow result can hold product, waste inventory, or trigger a recall.

Hygiena® helps ready-to-eat leaders take control with rapid, reliable diagnostics that keep food moving safely, from hygiene verification to pathogen and allergen detection, sterility, and centralized data management. Every hour counts. Delays or fragmented testing create ripple effects:

Cold storage fills fast while batches sit waiting.

Waste and rework eat into margins.

Non-validated or incomplete methods risk non-compliance.

Recalls can cost millions and erode consumer trust.

Leaders need quick, reliable answers that can withstand regulatory scrutiny and confidently release safe products. Hygiena delivers that assurance.

The Old Way vs. The Hygiena Way

| Traditional Testing | Hygiena Approach |

| Multi-day wait times slow release | Instant ATP cleaning verification, same shift rapid indicator organism tests, next-day PCR results |

| Separate systems for hygiene, pathogens, allergens | One connected portfolio across hygiene, pathogens, allergens, sterility |

| Specialized training required | Simple, easy-to-train workflows that fit stretched teams |

| Fragmented records hard to defend in audits | SureTrend® dashboards and audit-ready reports across sites |

Contamination Risks in Ready-to-Eat Production

Ready-to-eat manufacturing brings together diverse ingredients, frequent changeovers, and complex supply chains; all of which make contamination control uniquely challenging and demand constant vigilance from food safety teams. These everyday realities create multiple points where risk can enter the process:

- Frequent changeovers: Each switch introduces the risk of residues or allergen cross-contact.

- No final kill step: Multi-component foods carry inherent contamination risks.

- Complex supply chains: Raw materials like produce, herbs, and spices bring hidden hazards.

- Hygiena helps teams pinpoint, validate, and reduce risk fast.

One Partner for Reliable Ready-to-Eat Testing

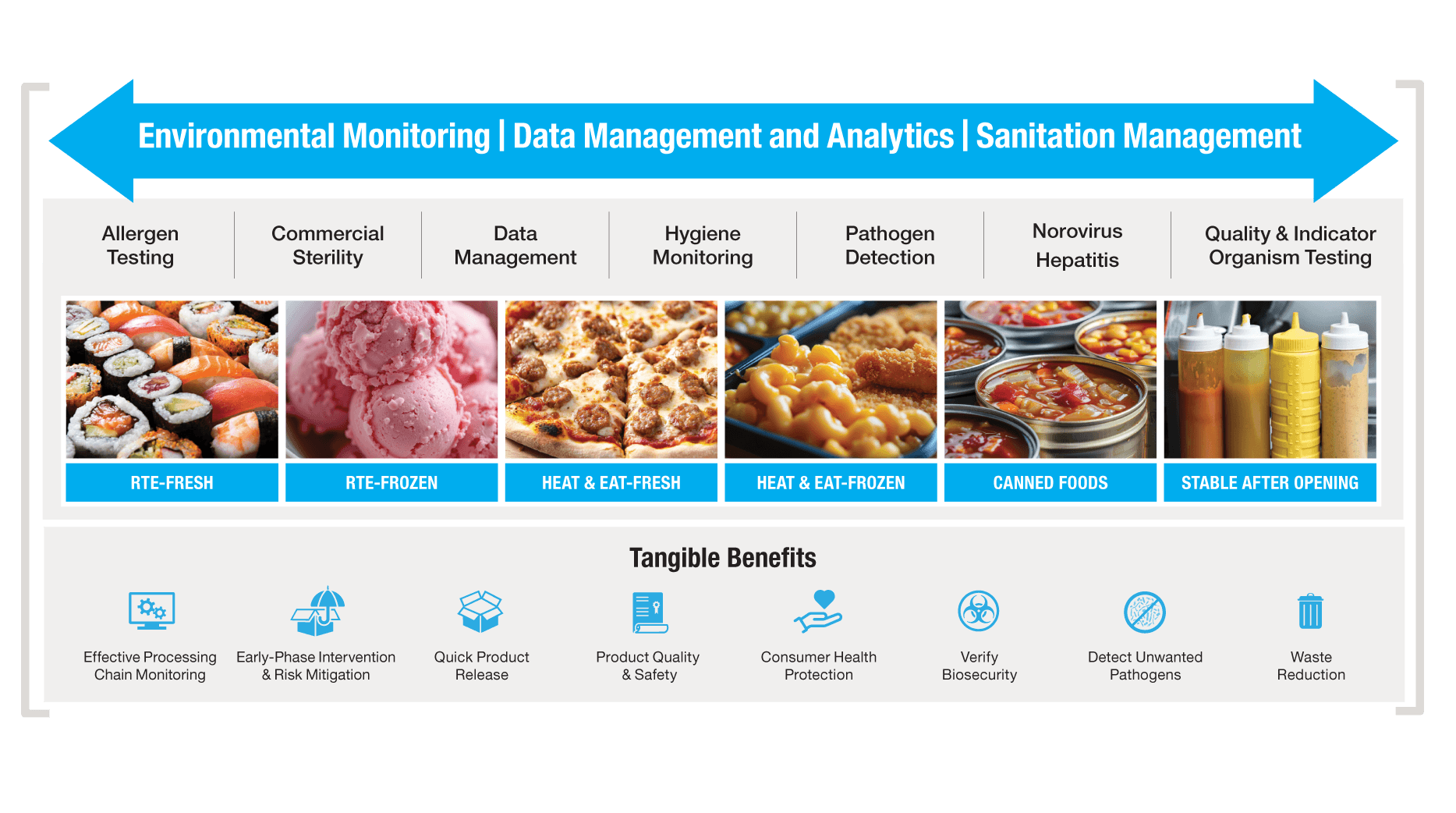

The Hygiena portfolio is comprehensive, covering environmental monitoring, surface hygiene, pathogen detection, allergen testing, quality indicators, commercial sterility, and complete sanitation and data management, all specifically designed for ready-to-eat operations.

See how ready-to-eat risk is reduced - from receipt to release

Explore the critical checkpoints that keep ready-to-eat production safe and compliant. From sanitation verification to allergen control and molecular testing, each step strengthens food safety and speeds confident release:

- Verify hygiene between changeovers

- Check allergens on high-risk surfaces

- Move from same-shift indicators to rapid PCR and sterility screening

- Consolidate all results into dashboards your team can act on

How Hygiena reduces risk, fast

Environmental and hygiene control

Allergen control

Pathogen detection

Commercial sterility

Mycotoxin and GMO screening

Animal Identification

Real-life Applications

- Why risky: Often eaten without additional cooking; multiple ingredients and handling steps increase exposure; no kill step.

- Primary concerns: Listeria, Salmonella and E. coli; allergen cross‑contamination.

- Why risky: Consumer mishandling, defrost time and reheat variability; potential Listeria regrowth; short room‑temp shelf life if abused.

- Primary concerns: Listeria and Salmonella; allergens.

- Why risky: Environmental sources from soil, water, animals; frequent handling post‑harvest.

- Primary concerns: Listeria monocytogenes, STEC/E. coli, Salmonella; for berries/water: Hep A/Norovirus.

- Why risky: Bulk handling with environmental exposure, adulteration risks in the supply chain, and strict allergen control are all critical risk factors.

- Primary concerns: Salmonella, allergens and mycotoxins matter despite low moisture.

Audit-Ready Confidence Backed by Global Validations

Our portfolio carries AOAC, Health Canada, and ISO validations by AFNOR, NordVal, or MicroVal for audit-accepted confidence in ready-to-eat matrices.

Validated methods across multiple technologies ensure defensible, regulator-recognized results:

- Pathogen detection: BAX® System and foodproof® PCR assays approved by AOAC, AFNOR, NordVal, MicroVal, and Health Canada.

- Allergen detection: AlerTox® and GlutenTox® ELISAs and PCR kits validated for complex food and surface matrices.

- Hygiene monitoring and indicators: ATP and microbial indicator methods supported by global recognition and internal QA programs.

Simplify Compliance and Strengthen Sanitation Management

Digital tools that simplify compliance, sanitation planning, and multi-site visibility.

- Combines ATP, indicator, allergen, and pathogen results into live dashboards.

- Generates audit-ready reports across plants.

- Identifies early warning trends for proactive interventions.

- Digitizes sanitation workflows and preventive maintenance schedules.

- Tracks corrective actions, verifications, and employee task completion.

- Integrates with SureTrend® for a full picture of hygiene performance and compliance readiness.

The Hygiena Difference

Worldwide Trusted Food Safety Testing Solutions and Expertise (H3)

Trusted by 90% of Forbes’ largest global food companies, Hygiena supports 90,000+ customers across 96 countries. With 160+ technical sales/support specialists and dedicated application labs, we deliver solutions designed for ready-to-eat production, hygiene monitoring, pathogen detection, allergen testing, sterility, sanitation management, and data analytics.

One global partner, every step of the ready-to-eat journey.

Frequently Asked Questions

1. How does contamination spread in RTE environments?

Moist areas, drains, and equipment crevices can harbor Listeria and Salmonella. Once biofilms develop, they can spread to other areas through water, tools and staff movement. Routine ATP and microbial monitoring helps detect hotspots early.

2. Why is Listeria so persistent in ready-to-eat facilities?

Listeria monocytogenes thrives in cold, damp areas and can survive normal cleaning. Regular environmental testing and validated PCR screening are essential to control it.

3. How quickly should RTE manufacturers get results?

Delays increase storage costs and risk. BAX® System and foodproof® PCR assays deliver same- or next-day detection of Listeria, Salmonella, and STEC for faster release decisions.

4. How does SureTrend® help food safety teams?

SureTrend® dashboards combine hygiene, allergen, and pathogen data to reveal trends, track corrective actions, and generate audit-ready reports across multiple sites.

5. How can plants verify cleaning between changeovers?

Using EnSURE® Touch with UltraSnap® or SuperSnap®, teams get instant ATP results to confirm sanitation before restarting production.

6. Why is allergen control critical in RTE production?

Frequent changeovers raise cross-contact risks. Rapid kits, such as AllerSnap®, AlerTox®, and GlutenTox®, confirm allergen-free lines and reduce recall potential.

7. What’s the value of validation in RTE testing?

Validated methods (AOAC, ISO, AFNOR, NordVal, MicroVal, Health Canada) provide defensible, regulator-accepted results for global audits and export confidence.

8. What tools speed up product release in RTE lines?

The Innovate™ Rapid Microbial Screening System delivers sterility results in approximately 30 minutes, clearing safe batches faster and, reducing cold-storage costs.

9. How can sanitation performance be tracked over time?

SureTrend® and KLEANZ® trend hygiene data, identify recurring failures, and automate preventive maintenance for continuous improvement.

10. What’s the difference between environmental and product testing?

Environmental tests check facility surfaces; product tests confirm finished food. Strong RTE programs use both for full contamination control.

11. How does Hygiena support multi-site operations?

Global technical teams and application labs help standardize methods, troubleshoot issues, and ensure consistent testing across all plants.

12. How can ingredient authenticity be verified?

foodproof® Animal ID, mycotoxin, and GMO screening assays confirm species and ingredient integrity before production.

13. What sets Hygiena apart in RTE food safety?

Hygiena unites hygiene verification, allergen and pathogen PCR, sterility testing, and digital data management enabling a single validated workflow from surface to release.